In 1986, Marc Jacobs started creating his own collections, and his forward-thinking, carefree designs are still in demand. Marc Jacobs(The Marc Jacobs Tote Bag) was infamously let go from Perry Ellis in 1992 for foreseeing the grunge trend, yet he kept designing for his own line even after accepting the position of creative director at Louis Vuitton in 1997. He has become one of the most influential designers in the world thanks to his immaculate execution of contemporary aesthetics. He has turned the Marc Jacobs label into a high-end manufacturing powerhouse that creates ready-to-wear, eyewear, footwear, fragrances, and more.

Table of Contents

How Tote Bags are Made

The Marc Jacobs Tote Bag – Whether you’re heading to the grocery store or bringing books to class, a tote bag will make your life much easier. They’re there to help you no matter what you choose to stuff them with. While tote bags are created from a range of materials, some of the most popular are made of plastic! Indeed, many of the items we wear, from faux leather coats to nylon stockings to polyester sweaters, are made of various forms of plastic.

What steps are involved in creating totes? What do fabrics and plastic have in common? Prepare to discover how these portable bags are created.

What Are Non Woven Fabrics?

The majority of woven tote bags are put together from fabric found at your local grocery or craft store. Weaved bags are often simple to manufacture in the comfort of your own home because the fabric is already prepared and processed. – The Marc Jacobs Tote Bag

Non-woven fabrics, on the other hand, are simply plastic disguised, and their name comes from the production technique. Non-woven fabrics are made of small fibres or melted plastic that have been chemically, thermally, or physically linked together during production, rather than thread.

Compared to woven materials, non-woven fabrics are more adaptable. They offer strength, robustness, softness, flexibility, and cushioning. Non-woven bags are used to produce a variety of items in addition to tote bags, including diapers, bedsheets, dusters, dryer sheets, tea bags, bandages, and much more.

What kind of plastic is used in the production of nonwoven fabrics?

Non-woven tote bags are often composed of polypropylene, while some are made of polyester. This is so that it can be easily worked with, has excellent properties like strength and resilience, and is very reasonably priced. In fact, employing polypropylene to produce tote bags has a lot of benefits:

- Inexpensive

- Water-Resistant

- Sustainable

- Durable

- Chemical-Resistant

Inexpensive

The Marc Jacobs Tote Bag – The majority of the time, plastics are priced by weight. Polypropylene is a low-cost plastic to use since it is not dense and has one of the lightest weights of any polymer.

resistant to water

The Marc Jacobs Tote Bag – Polypropylene is not able to absorb moisture, in contrast to fabrics that are extremely absorbent, like cotton. Tote bags are now simpler to wipe down or wash as needed.

Sustainable

The Marc Jacobs Tote Bag – Polypropylene, believe it or not, requires less fuel and emits less emissions when used in manufacturing. Because tote bags are reusable, they reduce the quantity of CO2 discharged into the sky.

The Marc Jacobs Tote Bag – Extremely elastic polypropylene fibres are strong. Your tote bags will survive for years to come because to its elasticity, which enables the material to maintain its shape even when subjected to torsion, bending, and stretching.

Resistant to Chemicals

While you should wash your tote bags on a regular basis, polypropylene tote bags are resistant to chemical characteristics. This ensures that scents from other products, such as nasty exercise socks, will not seep into the material.

What is Melt Spinning?

The fact that non-woven fabrics are produced using a technique called melt spinning is one of the factors contributing to their low cost and sustainability. The production of polypropylene non wovens produces nearly no environmental damage because it is a quick, easy procedure that requires heat. The entire process is much less expensive and takes significantly less time because it doesn’t require any purification steps or solvents (dyes). – The Marc Jacobs Tote Bag

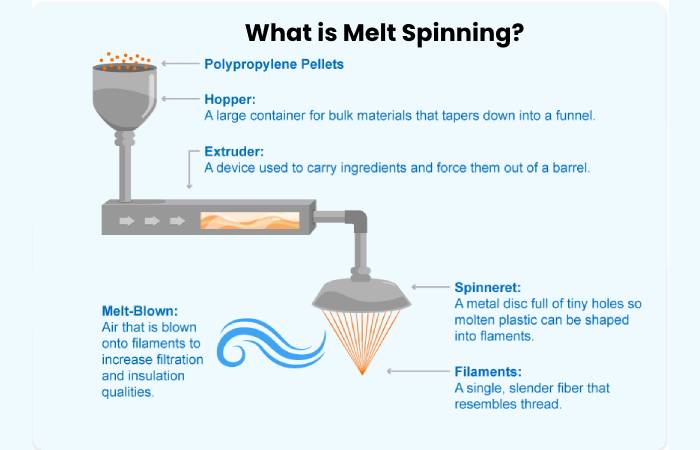

Look at this diagram to better understand melt spinning:

Tiny plastic pellets are thrown into a hopper and heated to nearly 500°F, where they melt into a syrup-like fluid that is used to create the tote bags.

To form filament fibres, the melted plastic is then extruded and forced through a spinneret.

Air is blown onto the filaments as they are forced out of the spinneret, and a machine starts spinning the various threads together.

Spunbonding is the process that causes the fibres to entangle so that when the fabric is pressed onto the conveyor belt, it forms uniform sheets of fabric.

Melt spinning is only utilised to produce particular polymers, such as nylon, polyester, and polypropylene, because some polymers dissolve or deteriorate at high temperatures. When heated, these plastics, unlike the others, transform into a molten liquid. These plastics would not be able to turn into synthetic fibres without this process.

(The Marc Jacobs Tote Bag)Tote Bags Glossary

The first step is understanding how plastic is utilised and the processes it goes through. When it comes to the manufacturing of tote bags, there are other phrases that are crucial to understand.

Fibers

Long, thin material used to make other textiles; when cut, it resembles feathers.

Gusset

The triangular piece of cloth that was placed into the sides of your tote bags was sturdy and long-lasting.

Transfer of Heat

A heat press printing procedure that uses high temperatures to put your brand into fabric.

Imprint

The imprint area of a promotional product is one of the most significant portions because it is where your logo or message is printed.

Polymer

Polypropylene and polyester are examples of large molecules that make up plastic chains.

Fabric that has been rolled up after going through the production process so it can be either immediately used or saved for the future.

Using the screen printing technique, a wax-like material called an emulsion is placed across a screen to imprint logos on products. – The Marc Jacobs Tote Bag

Even though there are many distinct technical jargon involved, it is these components that give tote bags their versatility and dependability. Without developments like the gusset or techniques like spun melt, tote bags would not have the same consistency as fabric or the same strength and durability.

How Are Custom Tote Bags Made?

Now that you’ve learned more about how non-woven totes receive their names and the terminologies related with the manufacturing process, let’s dive into each distinct stage!

- To make filaments, plastic polypropylene pellets are melted and pushed through a spinneret.

- Filaments are placed on a conveyor belt and pressed into sheets.

- When the sheets have cooled, they are rolled up into huge rolls of fabric.

- When the fabric is ready for use as a tote bag, it is measured and cut to size.

- The tote’s seams and handles are heat sealed or sewed together.

- The finished tote bags will be embellished with a bespoke logo, typically by screen printing or heat transfer. – The Marc Jacobs Tote Bag

Step 1

Melted polypropylene plastic particles are pushed through a spinneret in extremely small pieces. Due to this, the molten plastic transforms into filaments, which are incredibly thin fibres.

Step 2

The filaments are placed on a conveyor belt and flattened into sheets.

After that, the sheets are allowed to cool before proceeding to the next stage.

Step 3

The sheets are rolled into enormous rolls of fabric once they have cooled. They can be kept here until you’re ready to use them!

Step 4

When the fabric is ready to be turned into a tote bag, it is precisely measured and cut to shape. Because totes come in a variety of forms and sizes, measurements can be readily adjusted to obtain the appropriate size.

Step 5

The tote’s seams and handles are normally heat sealed after that. This implies that pressure and heat will be used to create a connection. The seams may also be stitched together, depending on the bag’s maker.

Step 6

The tote bags are now finished and ready to be adorned!

At this point, your logo will put to the centre of the tote bag, typically through screen printing or heat transfer.

You can display your custom design on one side of the tote bag or go all out and add designs on both sides.

Step 7

Your tote bags are excellently designed and prepared for packaging. They’ll be packaged flat, shipped, and delivered to you!

The Bottom Line

Tote bags may start out little, but by the time they’re finished and ready to use, they pack a tremendous punch (and plenty of goods).

Tote bags are a tote-tally amazing promotional tool to show off your business.

With so many benefits ranging from water resistance to affordability. – The Marc Jacobs Tote Bag

Helpful Resources

Essential Vitamins for Beautiful Skin

What Is Ginger Water?

The Acai Bowl: A Maximum Of Vitality For Healthy Breakfast